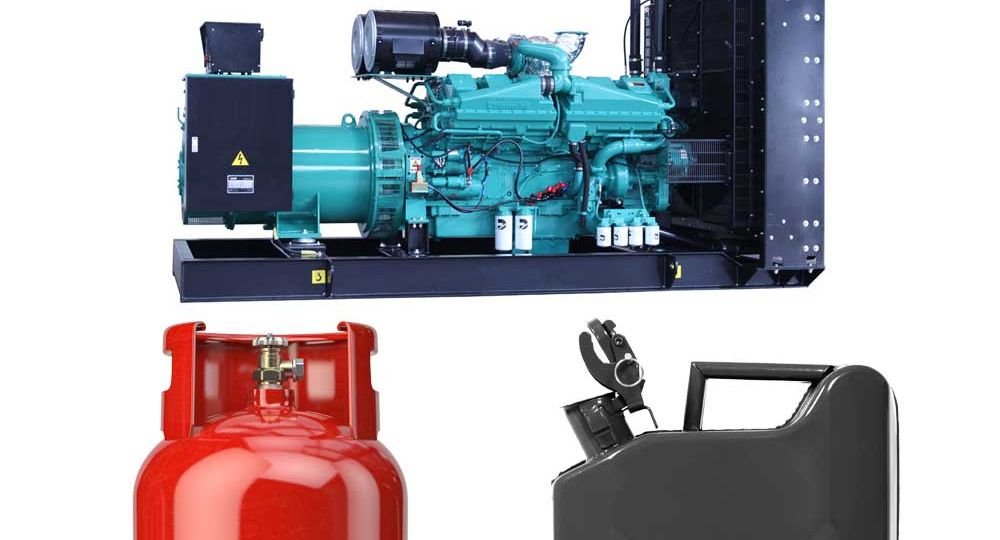

When you invest in a dual fuel generator, you're buying more than just a power source; you're securing peace of mind. These versatile machines, capable of running on both diesel and natural gas, offer unparalleled flexibility, whether you're facing a critical emergency or simply navigating fluctuating fuel prices. But to truly unlock their potential and ensure they're ready when you need them most, understanding Maintenance & Longevity Tips for Dual Fuel Generators isn't just a recommendation—it's a necessity.

Proper care transforms a high-tech machine into a steadfast guardian, always prepared to deliver continuous power. Neglecting it, however, can turn an asset into a liability. The good news? While these generators boast advanced technology, keeping them in prime condition is surprisingly straightforward with the right guidance.

At a Glance: Key Takeaways for Generator Longevity

- Fuel is Fundamental: Use stabilizers, expel water regularly, and always monitor both fuel types.

- Run It Right: Exercise your generator under load to prevent issues, but use "exercise mode" judiciously.

- Breathe Easy, Stay Cool: Ensure ample ventilation, keep air filters clean, and maintain coolant levels.

- Inspect and Protect: Conduct monthly visual checks and never skip professional annual servicing.

- Component Care: Secure electrical connections, lubricate moving parts, and store it wisely.

- Safety Above All: Understand and respect your generator's built-in protection systems and operating limits.

Why Dual Fuel Generators Demand Your Attention (and Reward It)

Dual fuel generators stand out for their adaptability. Imagine the relief of seamlessly switching from diesel to natural gas when one fuel source becomes scarce or expensive. This flexibility isn't just convenient; it's a strategic advantage, ensuring your critical systems remain operational, come what may. Beyond reliability, these generators often offer operational cost savings, as natural gas tends to be cheaper and burns cleaner, reducing the environmental footprint compared to diesel-only models. This cleaner burn also translates to less wear and tear on internal components, potentially extending the engine's life.

However, this sophistication means dual fuel generators have unique maintenance considerations. They combine the needs of a traditional combustion engine with the intricacies of handling two different fuel types. Regular upkeep, while seemingly a chore, is the secret sauce for maximizing their lifespan, maintaining peak efficiency, and ensuring they fire up reliably every single time. Think of it as preventative medicine for your power security.

Fueling Your Generator Right: The Lifeline of Power

Your generator's performance starts and ends with its fuel. Managing both diesel and natural gas effectively is paramount for smooth operation and longevity.

Avoiding Contamination: A Clear Fuel Line is a Happy Generator

Diesel fuel, in particular, is susceptible to degradation and water contamination. Condensation can build up in tanks, especially during temperature fluctuations, leading to water accumulation that can damage fuel injectors and other engine components.

- Stabilizers and Additives: For diesel, regularly incorporate high-quality fuel stabilizers and additives designed specifically for generators. These can prevent fuel breakdown, inhibit microbial growth, and keep your fuel system clean.

- Water Expulsion: Make it a habit to regularly drain any accumulated water from your fuel tank's sediment bowl or drain valve. This simple step can save you from costly repairs down the line. If you're looking for advanced solutions, some modern generators, like a Westinghouse dual fuel generator, might incorporate advanced filtration or fuel management systems that simplify this process.

Emergency Fuel Cutoff: Safety First, Always

Knowing how to quickly and safely shut off your generator's fuel supply is a critical safety measure. In an emergency, such as a fuel leak or an engine malfunction, a rapid cutoff can prevent escalation.

- Understand Your Model: Familiarize yourself with the location and operation of the manual fuel shut-off valves for both diesel and natural gas.

- Remote Kill Switches: High-end or permanently installed units often feature remote kill switches or emergency stop buttons. Ensure everyone who might operate the generator knows how to use these.

Monitoring Levels & Seamless Switching: Don't Get Caught Empty

A dual fuel generator's greatest strength is its ability to switch fuels. But this advantage hinges on having sufficient levels of both.

- Regular Checks: Make a habit of checking both the diesel tank and the natural gas supply (tank pressure or utility line) before and after each use, or as part of your monthly inspection.

- Anticipate Needs: During extended outages, you'll want to estimate your consumption rates for both fuels to ensure you have adequate reserves or a continuous natural gas supply.

Keeping the Engine Running Smoothly: Beyond Just Fuel

An idle generator is a sad generator. Engines are designed to work, and regular operation under the right conditions is vital for their health.

Regular Exercise: Under Load is Key

Many generator owners make the mistake of letting their units sit idle for months, only to find them balky when real power is needed.

- The "Why": Running your generator under load helps to burn off any carbon deposits, circulate lubricants, keep seals conditioned, and ensure all components are functioning correctly. It prevents "wet stacking," a common issue in diesel generators where unburnt fuel accumulates in the exhaust system.

- How Often: Aim to run your generator for at least 30 minutes to an hour once a month, ideally connecting it to some actual appliances or circuits to simulate a load. This doesn't mean powering your entire house, but enough to make the generator "work."

The "Exercise Mode" Dilemma: A Fine Balance

Some advanced generators come with an "exercise mode" that runs the engine for a short period without a load.

- Purpose: This mode is primarily for lubricating engine components, ensuring seals don't dry out, and circulating fluids. It conserves fuel by not drawing power.

- Caveat: While useful for light exercise, it doesn't fully replace running under a proper load. Use exercise mode sparingly and complement it with periodic full-load runs to truly keep the engine happy and healthy.

Breathing and Staying Cool: Vital Systems

Your generator's ability to "breathe" clean air and regulate its temperature directly impacts its efficiency and lifespan.

Proper Ventilation: A Non-Negotiable Safety Precaution

Operating any generator, especially one using natural gas, demands meticulous attention to ventilation.

- Prevent Buildup: Ensure your generator is always operated in a well-ventilated area, far from windows and doors, to prevent the buildup of deadly carbon monoxide from exhaust fumes and, crucially, to dissipate any potential natural gas or hydrocarbon vapors. These vapors are highly flammable and can lead to explosive incidents.

- Clear the Area: Regularly check that intake and exhaust vents are clear of obstructions like leaves, debris, or snow.

Air Filters: The Engine's Lungs

Just like your car, your generator's engine needs clean air to combust fuel efficiently.

- Check and Clean: Regularly inspect your air filter for dirt, dust, and debris. A clogged filter restricts airflow, forcing the engine to work harder, leading to overheating, reduced power, and increased fuel consumption.

- Replace as Needed: Depending on your operating environment (dusty vs. clean), you might need to clean or replace the air filter more frequently than the manufacturer's recommended schedule. Smart monitoring systems, if your generator has one, can alert you to filter issues.

Cooling System: Battling the Heat

Generators generate significant heat. An effective cooling system is essential to prevent engine overheating and damage.

- Clear Debris: Keep the cooling fins, radiators, and air intakes free from any obstructions. Dust, leaves, or even animal nests can severely impede airflow.

- Check Coolant Levels: For liquid-cooled generators, regularly check coolant levels and ensure the coolant is clean. Use the type of coolant specified by your manufacturer.

- Fan Inspection: Ensure cooling fans are operating correctly and free from any obstructions or damage.

The Proactive Approach: Inspections & Servicing

A combination of diligent self-checks and expert professional care will keep your dual fuel generator in peak condition.

Your Monthly Visual Check-up: The DIY Scan

Dedicate 15-30 minutes each month to a thorough visual inspection.

- Level Ground: Ensure the generator is sitting level.

- Ventilation: Confirm all ventilation pathways are clear.

- Leaks: Look for any signs of fuel, oil, or coolant leaks around the generator and its connections. Even a small drip can indicate a brewing problem.

- Loose Connections: Gently check electrical connections, fuel lines, and hoses for looseness or damage.

- Wear and Tear: Look for frayed wires, cracked hoses, or rust.

- Warning Labels: Make sure all safety and warning labels are clear and legible.

The Annual Deep Dive: Why Professional Servicing is Non-Negotiable

While your monthly checks are crucial, some issues require a specialist's touch.

- Certified Technicians: Schedule routine and annual inspections with certified technicians who specialize in dual fuel generators. They possess the expertise and specialized tools to:

- Perform comprehensive diagnostics.

- Check ignition systems, spark plugs, and fuel injectors.

- Calibrate fuel mixtures for optimal efficiency.

- Test safety shutdown features.

- Conduct thorough cleaning of internal components.

- Address complex electrical or mechanical issues before they become major problems.

- Warranty Compliance: Regular professional servicing also helps maintain your generator's warranty.

Tending to the Guts: Component Health for the Long Haul

Beyond the big systems, the smaller, often overlooked components play a huge role in your generator's reliability.

Electrical Connections: The Spark of Reliability

Corrosion and loose connections are silent killers of electrical systems.

- Secure and Clean: Regularly inspect all electrical connections, including battery terminals, for tightness and signs of corrosion. Clean any corrosion with a wire brush and apply dielectric grease to protect them. Loose connections can lead to intermittent power, system failures, and even fire hazards.

Lubrication: Keeping Things Moving

Friction is the enemy of any moving part. Proper lubrication keeps it at bay.

- Oil Checks: Regularly check your engine oil level and clarity. Dirty or low oil can lead to excessive wear and catastrophic engine failure. Change oil and oil filters according to the manufacturer's schedule.

- Moving Parts: Lubricate other moving parts, such as fan bearings or motor shafts, as recommended by the manual. Use the specified lubricants.

Thermostat: The Unsung Hero of Efficiency

The thermostat ensures your generator operates at its optimal temperature.

- Accuracy Matters: A faulty thermostat can lead to the engine running too hot or too cold, both of which reduce efficiency and increase wear. Regularly test or have your thermostat tested during professional servicing to ensure accurate temperature control, preventing unnecessary fuel consumption and premature component failure.

Smart Storage: Protecting Your Investment

Even when not in use, your generator needs care.

- Clean and Dry: Store your generator in a clean, dry, and secure location, protected from extreme temperatures and the elements.

- Fuel Preparation: Ensure fuel tanks are prepared for storage. For diesel, top off the tank with stabilized fuel to minimize condensation. For natural gas connections, ensure they are securely shut off.

- Battery Maintenance: Disconnect and maintain the battery with a trickle charger during extended storage to prevent self-discharge.

Safety First, Always: Operating Your Dual Fuel Generator Responsibly

The power a generator provides comes with inherent risks if not handled with respect. Prioritizing safety guidelines is non-negotiable.

Built-In Protections: Understanding Over-Pressure & Over-Temperature Systems

Modern dual fuel generators are equipped with sophisticated safety features.

- Know Your Systems: Familiarize yourself with your generator's over-pressure and over-temperature protection systems. These are designed to automatically shut down the unit if conditions exceed safe limits, preventing damage and potential hazards.

- Professional Setup: All installations, adjustments, and repairs related to these critical safety systems should only be performed by trained and qualified technicians. Never attempt to bypass or tamper with safety features.

Spotting Damage: When to Say "No" to a Component

Compromised components are accidents waiting to happen.

- Vigilance: During your monthly inspections, pay close attention to engine components. Any part showing signs of tampering, excessive heat exposure (discoloration, melting), or visible damage (cracks, dents) should be immediately flagged.

- Gas Leak Risk: Damaged fuel lines, connections, or seals can lead to dangerous gas leaks and malfunctions, especially with natural gas. If in doubt, do not operate the generator and call a professional.

Operating Within Limits: Respecting Design Compliance

Every generator is designed to operate within specific parameters. Pushing these limits is a recipe for disaster.

- Read the Manual: Always consult your generator's owner's manual for its specified temperature and pressure limits.

- Avoid Overloading: Do not overload your generator beyond its rated capacity. This can lead to overheating, component failure, and a higher risk of electrical fires or explosions.

- Adhere to Labels: Pay attention to all warning and instruction labels on the generator. Operating components outside their designated ranges can create dangerous conditions, risking fire, explosion, or serious injury.

Demystifying Dual Fuel Maintenance: Common Questions

Even with a comprehensive guide, specific questions often arise. Let's tackle some frequently asked ones.

How often should I run my dual fuel generator?

Most manufacturers recommend running your dual fuel generator under at least a 50% load for 30 minutes to an hour every month. This ensures internal components are lubricated, seals remain pliable, and fuel doesn't "wet stack" or degrade in the system. If your unit has an exercise mode, you can use that for very light exercise, but it shouldn't entirely replace a proper load test.

Can I use car oil in my generator?

Generally, no. While some generators might tolerate automotive oil in a pinch, it's best to always use the specific type and weight of engine oil recommended by your generator's manufacturer. Generator engines operate under different load conditions and often at higher, sustained RPMs compared to car engines, requiring lubricants with specific properties to protect their internal components effectively. Using the wrong oil can void your warranty and lead to premature engine wear.

What's the biggest mistake people make with dual fuel generator maintenance?

The biggest mistake is often neglect. Many owners treat their generator as an "out of sight, out of mind" appliance, only to discover it won't start when an emergency hits. Failing to perform regular monthly run-tests under load, skipping annual professional servicing, and ignoring fuel management (like using stabilizers or expelling water) are common pitfalls that lead to costly repairs or complete generator failure.

What are the signs my generator needs professional servicing?

Beyond the scheduled annual service, watch for these red flags: difficulty starting, excessive smoke (especially blue or black), unusual noises (grinding, knocking, persistent squealing), decreased power output, frequent shutdowns, visible fuel or oil leaks, or any warning lights illuminated on the control panel. If you notice any of these, it's time to call a certified technician.

Your Power Security Playbook: Final Steps for Generator Longevity

A dual fuel generator is a significant investment in your home or business's resilience. Protecting that investment boils down to consistent, informed maintenance. By following these comprehensive tips, you're not just performing routine tasks; you're actively safeguarding your power supply, extending the life of your machine, and ensuring it operates efficiently and safely for years to come.

Make these maintenance practices a part of your regular routine. Keep your owner's manual handy, create a maintenance log, and don't hesitate to consult with certified professionals for any concerns beyond your expertise. With a little proactive care, your dual fuel generator will be a reliable ally, ready to light up your life whenever the grid goes dark.